Crack propagation

In CalculiX a rather simple model to calculate cyclic crack propagation is

implemented. In order to perform a crack propagation calculation the following

procedure is to be followed:

- A static calculation (usually called a Low Cycle Fatigue = LCF calculation) for the uncracked structure (using volumetric elements) for one or more steps must have been performed

and the results (at least stresses; if applicable, also the temperatures)

must have been stored in a frd-file.

- Optionally a frequency calculation (usually called a High Cycle

Fatigue = HCF calculation) for the uncracked structure has been

performed and the results (usually stresses) have been stored in a frd-file.

- For the crack propagation itself a model consisting of at

least all cracks to be considered meshed using S3-shell

elements must be created. The orientation of all shell elements used to

model one and the same crack should consistent, i.e. when viewing the crack

from one side of the crack shape all nodes should be numbered clockwise or all nodes

should be numbered counterclockwise. Preferably, also the mesh of the uncracked

structure should be contained (the crack propagation can be easier

interpreted if the structure in which the crack propagates is also

visualized) .

- The material parameters for the crack propagation law implemented in

CalculiX must have been determined. Alternatively, the user may code

his/her own crack propagation law in routine crackrate.f.

- The procedure *CRACK PROPAGATION must have

been selected with appropriate parameters. Within the *CRACK PROPAGATION

step the optional keyword card *HCF may have been selected.

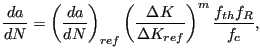

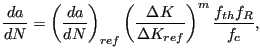

In CalculiX, the following crack propagation law has been implemented:

|

(825) |

where

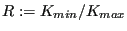

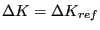

accounts for the threshold range,

for the critical cut-off and

![$\displaystyle f_R = \left[ \frac{1}{(1-R)^{1-w}} \right]^m$](img2422.png) |

(828) |

for the

influence. The material constants have to be entered by using

a *USER MATERIAL card with the following 8 constants

per temperature data point

(in that order):

influence. The material constants have to be entered by using

a *USER MATERIAL card with the following 8 constants

per temperature data point

(in that order):

![$ \left ( \frac{da}{dN} \right ) _{ref} [L/cycle]$](img2424.png) ,

,

![$ \Delta

K_{ref}[F/L^{3/2}] $](img2425.png) ,

,

![$ m [-]$](img2426.png) ,

,

![$ \epsilon [-]$](img2427.png) ,

,

![$ \Delta K_{th} [F/L^{3/2}]$](img2428.png) ,

,

![$ \delta [-]$](img2429.png) ,

,

![$ K_c

[F/L^{3/2}]$](img2430.png) and

and  [-], were

[-], were ![$ [F]$](img2432.png) is the unit of force and

is the unit of force and ![$ [L]$](img2433.png) of

length. Notice

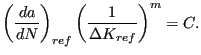

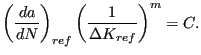

that the first part of the law corresponds to the Paris law. Indeed the classical Paris constant C can be obtained

from:

of

length. Notice

that the first part of the law corresponds to the Paris law. Indeed the classical Paris constant C can be obtained

from:

|

(829) |

Vice versa,

can be obtained from

can be obtained from  using the above

equation once

using the above

equation once

has been chosen. Notice that

has been chosen. Notice that

is the rate for which

is the rate for which

(just considering the Paris

range). For a user material, a maximum of 8 constants can be defined per line

(cf. *USER MATERIAL). Therefore, after entering the 8

crack propagation constants, the corresponding temperature has to be entered

on a new line.

(just considering the Paris

range). For a user material, a maximum of 8 constants can be defined per line

(cf. *USER MATERIAL). Therefore, after entering the 8

crack propagation constants, the corresponding temperature has to be entered

on a new line.

The crack propagation calculation consists of a number of increments during

which the crack propagates a certain amount. For each increment in a LCF

calculation the following

steps are performed:

- The actual shape of the cracks is analyzed, the crack fronts are

determined and the stresses and temperatures (if applicable, else zero)

at the crack front nodes are interpolated from the stress and temperature

field in the uncracked structure.

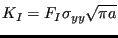

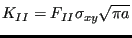

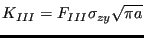

- The stress tensor at the front nodes is projected on the local

tangent plane yielding a normal component (local y-direction), a shear component orthogonal

to the crack front (local x-direction) and one parallel to the crack

front (local z-direction), leading to the

K-factors

,

,  and

and  using the formulas:

using the formulas:

|

(830) |

|

(831) |

|

(832) |

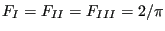

where  ,

,  and

and  are shape factors taking the form

are shape factors taking the form

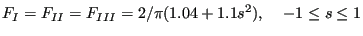

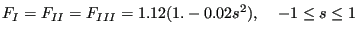

|

(833) |

for subsurface cracks,

|

(834) |

for surface cracks spanning an angle  and

and

|

(835) |

for surface cracks spanning an angle of 0 (i.e. a one-sided crack in a

two-dimensional plate). For an angle in between 0 and  the shape

factors are linearly interpolated in between the latter two formulas. In

the above formulas

the shape

factors are linearly interpolated in between the latter two formulas. In

the above formulas  is a local coordinate along the crack front,

taking the values

is a local coordinate along the crack front,

taking the values  and

and  at the free surface and 0 in the middle

of the front. If the user prefers to use more detailed shape factors,

user routine crackshape.f can be recoded.

at the free surface and 0 in the middle

of the front. If the user prefers to use more detailed shape factors,

user routine crackshape.f can be recoded.

- The crack length

in the above formulas is determined in two

different ways, depending on the value of the parameter LENGTH on the

*CRACK PROPAGATION card:

in the above formulas is determined in two

different ways, depending on the value of the parameter LENGTH on the

*CRACK PROPAGATION card:

- for LENGTH=CUMULATIVE the crack length is obtained by

incrementally adding the crack propagation increments to the

initial crack length. The initial length is determined using the

LENGTH=INTERSECTION method.

- for LENGTH=INTERSECTION a plane locally orthogonal to the

crack front e.g. at location

of the crack front is constructed and subsequently a

second intersection

of the crack front is constructed and subsequently a

second intersection  of this plane with the crack boundary is sought. The crack boundary

is the outer line of that part of the shell mesh which is inside the

structure. It consists of one or more crack front(s) and for surface

cracks of intersection(s) of the shell mesh with the outer surface of

the structure. Then, a point

of this plane with the crack boundary is sought. The crack boundary

is the outer line of that part of the shell mesh which is inside the

structure. It consists of one or more crack front(s) and for surface

cracks of intersection(s) of the shell mesh with the outer surface of

the structure. Then, a point  on the

straight line between

on the

straight line between  and

and  is determined, which maximizes

the minimum distance between

is determined, which maximizes

the minimum distance between  and any node along the crack

front(s) belonging to the crack at stake. The distance between

and any node along the crack

front(s) belonging to the crack at stake. The distance between  and

and  is the crack length

is the crack length

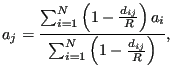

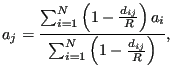

Subsequently, the crack length is smoothed along the crack front

according to:

|

(836) |

where the sum is over the  closest nodes,

closest nodes,  is the Euclidean

incremental distance between node

is the Euclidean

incremental distance between node  and

and  , and

, and  is the distance

between node

is the distance

between node  and the

farthest of these nodes.

and the

farthest of these nodes.  is a fixed fraction of the total number of

nodes along the front, e.g. 90 %.

is a fixed fraction of the total number of

nodes along the front, e.g. 90 %.

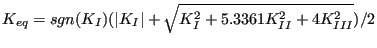

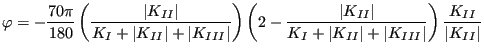

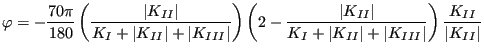

- From the stress factors an equivalent K-factor and deflection angle

is calculated using a light modification of the formulas by

Richard [83] in order to cope with negative

is calculated using a light modification of the formulas by

Richard [83] in order to cope with negative  values as well:

values as well:

|

(837) |

and

|

(838) |

for  and

and  else. Subsequenty,

else. Subsequenty,  and

and

are smoothed in the same way as the crack length. Finally,

if any of the deflection angles exceeds the maximum defined by the user

(second entry underneath the *CRACK

PROPAGATION card) all values along the front are

scaled appropriately.

are smoothed in the same way as the crack length. Finally,

if any of the deflection angles exceeds the maximum defined by the user

(second entry underneath the *CRACK

PROPAGATION card) all values along the front are

scaled appropriately.

Notice that at each crack front location as many  and

and

values are calculated as there are steps in the static

calculation of the uncracked structure.

values are calculated as there are steps in the static

calculation of the uncracked structure.

- The crack propagation increment for this increment is

determined. It is the minimum of:

- The user defined value (first entry underneath the *CRACK

PROPAGATION card)

- one fifth of the minimum crack front curvature

- one fifth of the smallest crack length

- The crack propagation rate at every crack front location is

determined. If there is only one step it results from the direct

application of the crack propagation law with

. For

several steps the maximum minus the minimum of

. For

several steps the maximum minus the minimum of  is taken. Notice that the crack

rate routine is documented as a user subroutine: for missions

consisting of several steps the user can define his/her own procedure

for more complex procedures such as cycle extraction. The maximum value

of

is taken. Notice that the crack

rate routine is documented as a user subroutine: for missions

consisting of several steps the user can define his/her own procedure

for more complex procedures such as cycle extraction. The maximum value

of  across all crack front locations determines the number of

cycles in this increment.

across all crack front locations determines the number of

cycles in this increment.

- For each crack front node the location of the propagated node is

determined. This node lies in a plane locally orthogonal to the

tangent vector along the front. To this end a local coordinate system

is created (the same as for the calculation of

,

,  and

and

) consisting of:

) consisting of:

- The local tangent vector

.

.

- The local normal vector obtained by the mean of the normal

vectors on the shell elements to which the nodal front position

belongs. This vector is subsequently projected into the plane

normal to

and normalized to obtain a vector

and normalized to obtain a vector

.

.

- a vector in the propagation direction

. This assumes that the

tangent vector was such that the corkscrew rule points into

direction

. This assumes that the

tangent vector was such that the corkscrew rule points into

direction

when running along the crack front in

direction

when running along the crack front in

direction

.

.

- Then, new nodes are created in between the propagated nodes such

that they are equidistant. The target distance in between these nodes

is the mean distance in between the nodes along the initial crack front.

- Finally, new shell elements are generated covering the crack

propagation increment and the results (K-values, crack length etc.)

are stored in frd-format for visualization. Then, a new increment can

start. The number of increments is governed by the INC parameter on the

*STEP card.

For a combined LCF-HCF calculation, triggered by the *HCF keyword in the

*CRACK PROPAGATION procedure the picture is slightly more complicated. On the

*HCF card the user defines a scaling factor and a step from the static

calculation on which the HCF loading is to be applied. This is usually the

static loading at which the modal excitation occurs. At this step a HCF cycle

is considered consisting of the LCF+HCF and the LCF-HCF loading. The effect is as follows:

- If this cycle leads to propagaton and HCF propagation is not allowed

(MAX CYCLE= 0 on the *HCF card; this is default) the program stops with

an appropriate error message.

- If it leads to propagation and HCF propagation is allowed (MAX

CYCLE

0 on the *HCF card) the number of cycles is determined to

reach the desired crack propagation in this increment and

the next increment is started. No LCF propagation is considered in this

increment.

0 on the *HCF card) the number of cycles is determined to

reach the desired crack propagation in this increment and

the next increment is started. No LCF propagation is considered in this

increment.

- If it does not lead to HCF propagation, LCF propagation is

considered for the static loading in which the LCF loading of the

step to which HCF applies is repaced by LCF+HCF loading. The

propagation is calculated as usual.

The output of a *CRACK PROPAGATION step is selected by using the

parameter KEQ on the *NODE FILE card. Then, a data set is created in the frd-file consisting of the

following information (most of this information can be changed in user

subroutine crackrate.f):

- The dominant step. This is the step

with the largest

(over all steps). If the dominant step is a HCF

induced step, step numbers -1 and -2 are used to denominate the LCF-HCF

step and the LCF+HCF step,respectively.

(over all steps). If the dominant step is a HCF

induced step, step numbers -1 and -2 are used to denominate the LCF-HCF

step and the LCF+HCF step,respectively.

- DeltaKEQ: the value of

for the main cycle. In the

present implementation this corresponds to the largest value of

for the main cycle. In the

present implementation this corresponds to the largest value of  (over all steps).

(over all steps).

- KEQMIN: the minimal value of

(over all steps).

(over all steps).

- KEQMAX: the largest value of

(over all steps).

(over all steps).

- K1WORST: the largest value of

multiplied by its sign (over all steps).

multiplied by its sign (over all steps).

- K2WORST: the largest value of

multiplied by its sign (over all steps).

multiplied by its sign (over all steps).

- K3WORST: the largest value of

multiplied by its sign (over all steps).

multiplied by its sign (over all steps).

- PHI: the deflection angle

.

.

- R: the R-value of the main cycle. In the present implementation

this is zero.

- DADN: the crack propagation rate.

- KTH: not used.

- INC: the increment number. This is the same for all nodes along one

and the same crack front.

- CYCLES: the number of cycles since the start of the calculation. This

number is common to all crack front nodes.

- CRLENGTH: crack length.

- DOM_SLIP: not used

Since the jobname.frd file is created from scratch in every *CRACK

PROPAGATION step (this is because every *CRACK

PROPAGATION step changes the number of nodes and elements in the model due to

the growing crack) it does not make sense to have more than

one such step in an 输入卡. In fact, any other step is senseless and

ideally the *CRACK PROPAGATION step should be the only step in the deck. If

the user defines more than one *CRACK PROPAGATION step in his/her 输入卡,

the jobname.frd file will only contain the output requested, if any, from the last *CRACK

PROPAGATION step. This rule also applies to restart calculations.

![$\displaystyle = 1-\exp \left[ \epsilon (1 - \frac{\Delta K}{\Delta K_{th}} ) \right], \;\;\; \Delta K > \Delta K_{th}$](img2417.png)

![$\displaystyle =1-\exp \left[ \delta \left( \frac{K_{max}}{K_c} -1 \right) \right], \;\;\; K_{max} < K_c$](img2420.png)

![$\displaystyle f_R = \left[ \frac{1}{(1-R)^{1-w}} \right]^m$](img2422.png)

![]() influence. The material constants have to be entered by using

a *USER MATERIAL card with the following 8 constants

per temperature data point

(in that order):

influence. The material constants have to be entered by using

a *USER MATERIAL card with the following 8 constants

per temperature data point

(in that order):

![]() ,

,

![]() ,

,

![]() ,

,

![]() ,

,

![]() ,

,

![]() ,

,

![]() and

and ![]() [-], were

[-], were ![]() is the unit of force and

is the unit of force and ![]() of

length. Notice

that the first part of the law corresponds to the Paris law. Indeed the classical Paris constant C can be obtained

from:

of

length. Notice

that the first part of the law corresponds to the Paris law. Indeed the classical Paris constant C can be obtained

from:

![]() can be obtained from

can be obtained from ![]() using the above

equation once

using the above

equation once

![]() has been chosen. Notice that

has been chosen. Notice that

![]() is the rate for which

is the rate for which

![]() (just considering the Paris

range). For a user material, a maximum of 8 constants can be defined per line

(cf. *USER MATERIAL). Therefore, after entering the 8

crack propagation constants, the corresponding temperature has to be entered

on a new line.

(just considering the Paris

range). For a user material, a maximum of 8 constants can be defined per line

(cf. *USER MATERIAL). Therefore, after entering the 8

crack propagation constants, the corresponding temperature has to be entered

on a new line.

![]() ,

, ![]() and

and ![]() are shape factors taking the form

are shape factors taking the form

![]() and

and

![]() the shape

factors are linearly interpolated in between the latter two formulas. In

the above formulas

the shape

factors are linearly interpolated in between the latter two formulas. In

the above formulas ![]() is a local coordinate along the crack front,

taking the values

is a local coordinate along the crack front,

taking the values ![]() and

and ![]() at the free surface and 0 in the middle

of the front. If the user prefers to use more detailed shape factors,

user routine crackshape.f can be recoded.

at the free surface and 0 in the middle

of the front. If the user prefers to use more detailed shape factors,

user routine crackshape.f can be recoded.

![]() closest nodes,

closest nodes, ![]() is the Euclidean

incremental distance between node

is the Euclidean

incremental distance between node ![]() and

and ![]() , and

, and ![]() is the distance

between node

is the distance

between node ![]() and the

farthest of these nodes.

and the

farthest of these nodes. ![]() is a fixed fraction of the total number of

nodes along the front, e.g. 90 %.

is a fixed fraction of the total number of

nodes along the front, e.g. 90 %.

![]() and

and ![]() else. Subsequenty,

else. Subsequenty, ![]() and

and

![]() are smoothed in the same way as the crack length. Finally,

if any of the deflection angles exceeds the maximum defined by the user

(second entry underneath the *CRACK

PROPAGATION card) all values along the front are

scaled appropriately.

are smoothed in the same way as the crack length. Finally,

if any of the deflection angles exceeds the maximum defined by the user

(second entry underneath the *CRACK

PROPAGATION card) all values along the front are

scaled appropriately.

![]() and

and

![]() values are calculated as there are steps in the static

calculation of the uncracked structure.

values are calculated as there are steps in the static

calculation of the uncracked structure.