下一个: Tension-only and compression-only materials. 上一级: Materials 上一页: Plasticity with Johnson-Cook hardening. 目录

The theory and algorithms used to code the classical Mohr-Coulomb plasticity model are primarily taken from [100] and [21] and the references therein.

The Mohr-Coulomb plasticity is non-associative with a piecewise linear yield

surface ![]() an a piecewise linear plastic potential

an a piecewise linear plastic potential ![]() . The basic idea is

that the shear stress at which plastic flow occurs increases with increasing

pressure, similar to contact sliding. This is illustrated in Figure

140 showing the shear stress

. The basic idea is

that the shear stress at which plastic flow occurs increases with increasing

pressure, similar to contact sliding. This is illustrated in Figure

140 showing the shear stress ![]() versus normal stress

versus normal stress

![]() .

.

![]() are the principal

stresses.

are the principal

stresses.

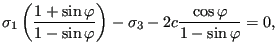

The yield surface satisfies:

| (388) |

where ![]() is the cohesion. This is equivalent to (cf. Figure 140)

is the cohesion. This is equivalent to (cf. Figure 140)

|

(389) |

or

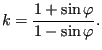

where

|

(391) |

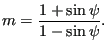

![]() is called the friction angle. Similarly, the plastic potential is

defined by:

is called the friction angle. Similarly, the plastic potential is

defined by:

| (392) |

where

|

(393) |

![]() is called the dilation angle. It describes to what extent the volume of

the material changes due to shear motion. For a positive value of

is called the dilation angle. It describes to what extent the volume of

the material changes due to shear motion. For a positive value of ![]() the

volume increases, as for dense sand. For a negative value the volume

decreases, as for loose sand. In the latter case the grains fit better due to

the motion. You can easily illustrate this by pouring suger in a bowl. Shaking

the bowl the volume will decrease and more sugar will fit.

the

volume increases, as for dense sand. For a negative value the volume

decreases, as for loose sand. In the latter case the grains fit better due to

the motion. You can easily illustrate this by pouring suger in a bowl. Shaking

the bowl the volume will decrease and more sugar will fit.

As mentioned, the yield surface is piecewise linear, so the gradient of the surface is not continuous. This complicates matters. Now, looking at the yield surface and plastic potential it can be observed that it contains only principal stresses. Assuming the material to be elastically isotropic, this allows us to perform all operations in principal stress space, thereby reducing the tensors to vectors. This was first proposed in [20].

Replacing

![]() by

by ![]() for simplicity, the yield

surface as defined in Equation (390) defines in three-dimensional

space one of six faces of a irregular pyramid with central axis in

for simplicity, the yield

surface as defined in Equation (390) defines in three-dimensional

space one of six faces of a irregular pyramid with central axis in ![]() direction. The other faces correspond to sectors in which the order of

direction. The other faces correspond to sectors in which the order of

![]() is different.

is different.

Figure 141 shown a view

on a plane orthogonal to the ![]() axis and through the origin. The six

sectors are bordered by planes going through the x-, y- and z- axes and

containing the

axis and through the origin. The six

sectors are bordered by planes going through the x-, y- and z- axes and

containing the ![]() -axis. The cross section of this plane with the yield

surface is an irregular hexagon (dashed line). Since the principal stresses

can always be rearranged such that

-axis. The cross section of this plane with the yield

surface is an irregular hexagon (dashed line). Since the principal stresses

can always be rearranged such that

![]() it is sufficient to look at

that sector (labeled 1) and the neighboring ones (labeled 6 and 2).

it is sufficient to look at

that sector (labeled 1) and the neighboring ones (labeled 6 and 2).

Figure 142 shows the yield surface viewed from the apex and

looking in the direction of

![]() . In the sectors of interest the

normal to the surface

. In the sectors of interest the

normal to the surface

![]() is shown. For sector 1 this is

immediately clear from Equation (390) which can be written as

is shown. For sector 1 this is

immediately clear from Equation (390) which can be written as

![]() . A vector along

the interection lines of the pyramid faces is obtained by taking the cross

product of the normal of the neighboring faces,e.g.

. A vector along

the interection lines of the pyramid faces is obtained by taking the cross

product of the normal of the neighboring faces,e.g.

![]() . The apex of the pyramid is obtained

by substituting

. The apex of the pyramid is obtained

by substituting

![]() in Equation (390): it yields

in Equation (390): it yields

|

(394) |

Therefore, the equation of the intersection line between section 6 and 1

satisfied

![]() . Its intersection with the plane

. Its intersection with the plane

![]() leads to

leads to

|

(395) |

yielding the location of point A in Figure 141. For point B one gets

|

(396) |

which is farther away from the origin since ![]() . The normal to the

plastic potential surface is labeled

. The normal to the

plastic potential surface is labeled

![]() and amounts for sector 1

to

and amounts for sector 1

to ![]() . Similar expressions apply to the other sectors.

. Similar expressions apply to the other sectors.

The governing equations of an elastic material with Mohr-Coulomb plasticity read:

Elastic stress-strain relations

| (397) |

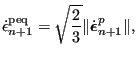

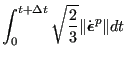

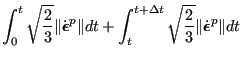

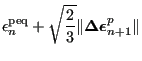

Internal variable relationship

| (398) |

Yield surface

| (399) |

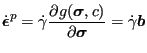

Evolution equations

|

(400) |

Kuhn-Tucker equations

| (401) |

Consistency condition

| (402) |

Notice that in the above equatons

![]() and

and

![]() are vectors in principal space.

are vectors in principal space.

In order to explain the numerical procedure it is assumed that all variables

are known at the end of increment ![]() (corresponding to time

(corresponding to time ![]() ) and that

their values are sought at the end of increment

) and that

their values are sought at the end of increment ![]() (corresponding to time

(corresponding to time

![]() ). The input to the algorithm is a change on total strain

). The input to the algorithm is a change on total strain

![]() .

.

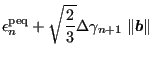

At first it is assumed that now plasticity occurs in the new increment, i.e.:

| (403) |

| (404) |

| (405) |

| (406) |

If

| (407) |

the solution is found. If not,

![]() and due to the Kuhn-Tucker equations

and due to the Kuhn-Tucker equations

![]() is

required. The stress at

is

required. The stress at ![]() can be written as:

can be written as:

| (408) | |||

| (409) | |||

| (410) | |||

| (411) | |||

| (412) |

In the last equation the evolution equation was used (flow rule). Defining

![]() , satisfying

the yield surface now requires:

, satisfying

the yield surface now requires:

| (413) |

Notice that

![]() points in the direction of the stress correction

w.r.t. the trial stress. In order to solve this equation a relationship between

points in the direction of the stress correction

w.r.t. the trial stress. In order to solve this equation a relationship between

![]() and

and

![]() is needed. Now,

is needed. Now,

![]() is defined as:

is defined as:

|

(414) |

from which:

|

(415) | ||

|

(416) | ||

|

(417) | ||

|

(418) | ||

|

(419) |

Defining

![]() and

and

![]() the yield equation

now amounts to:

the yield equation

now amounts to:

| (420) |

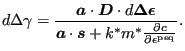

This is a nonlinear equation in

![]() . Using the

Newton-Raphson procedure the first derivative is needed, which yields:

. Using the

Newton-Raphson procedure the first derivative is needed, which yields:

|

(421) |

Starting with an initial guess

![]() , one arrives at

, one arrives at

![]() by solving the equation:

by solving the equation:

| (422) |

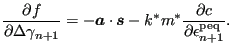

or

![$\displaystyle \left [ - \boldsymbol{a} \cdot \boldsymbol{s} - k^*m^* \left . \f...

...a_{n+1}^{(k)} \boldsymbol{s} \right ] - k^* c(\epsilon_{n+1}^{\text{peq},(k)}),$](img1450.png) |

(423) |

where

| (424) |

This works as long a the return is to a face of the yield surface. Since the

return vector for sector 1 is

![]() one

can graphically plot the region in three-dimensional principal stress space

which is returned to the yield face in sector 1 (Figure 143). It

is the space for which

one

can graphically plot the region in three-dimensional principal stress space

which is returned to the yield face in sector 1 (Figure 143). It

is the space for which

| (425) |

This is called region I. The space within sector 1 in between region I and

sector 2 and underneath the apex is mapped onto the intersection line of face 1 and face 2 of the

yield surface (characterized by the equation

![]() ). It is characterized by the equations

). It is characterized by the equations

| (426) |

and is called region II of sector 1. Similary for the space in between region I and sector 6 and underneath the apex satisfying

| (427) |

This is region III. Finally, the region above the apex corresponding to

| (428) |

is returned to the apex and is called region IV.

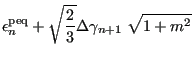

Returning the trial stress to the intersection line of two yield faces implies that the final state has to satisfy both face equations. The equivalent plastic strain now satisfies:

| (429) |

and the yield surface equations amount to:

| 0 | (430) | ||

| (431) |

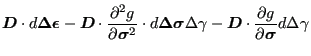

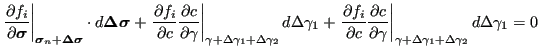

Applying Newton-Raphson now leads to:

![$\displaystyle [A] \cdot \begin{Bmatrix}\Delta \Delta \gamma_1 \\ \Delta \Delta \gamma_2 \end{Bmatrix} _{n+1}^{(k)} = \{B\},$](img1463.png) |

(432) |

where

![$\displaystyle [A]= \begin{bmatrix}- \boldsymbol{a_1} \cdot \boldsymbol{s_1} - k...

...on^{\text{peq}} } \right \vert _{\epsilon_{n+1}^{\text{peq},(k)}} \end{bmatrix}$](img1464.png) |

(433) |

and

![$\displaystyle \{B\}= \begin{Bmatrix}\boldsymbol{a_1} \cdot \left [ \boldsymbol{...

...oldsymbol{s_2} \right ] - k^* c(\epsilon_{n+1}^{\text{peq},(k)}) \end{Bmatrix}.$](img1465.png) |

(434) |

For a return to the apex the yield equations of sector 1, 2 and 6 have to be satisfied yielding 3 equations in 3 unknowns.

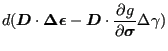

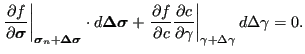

To calculate the consistent tangent the change of stress due to a change in total strain is needed. The change of stress in the present increment amounts to:

| (435) | |||

| (436) | |||

|

(437) | ||

|

(438) | ||

| (439) |

Now, a relationship between

![]() and

and

![]() is needed. This is obtained from the yield equation:

is needed. This is obtained from the yield equation:

| (440) |

from which

|

(441) |

Substituting the previously obtained expression for

![]() yields (dropping the bound of the derivatives to simplify the

notation; the derivatives are to be taken at the end of the present increment):

yields (dropping the bound of the derivatives to simplify the

notation; the derivatives are to be taken at the end of the present increment):

|

(442) |

from which

|

(443) |

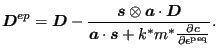

Finally one obtains for the elastoplastic consistent tangent

|

(444) |

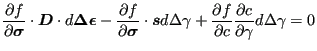

The derivation of the elastoplastic consistent tangent for a return to the intersection between face 1 and face 2 is similar. Now, a change in stress increment amounts to:

| (445) |

A relationship between the change in

![]() and the change in

and the change in

![]() can again be obtained by considering the

adjacent yield

faces (i=1,2):

can again be obtained by considering the

adjacent yield

faces (i=1,2):

| (446) |

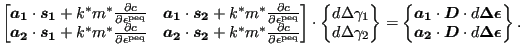

from which

|

(447) |

or

|

(448) |

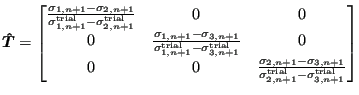

Denoting the inverse of the left hand matrix by ![]() the solution of the

above system can be written as:

the solution of the

above system can be written as:

| (449) | |||

| (450) |

leading to:

| (451) |

The derivation for the return to the apex is similar (now three equations have to be satisfied).

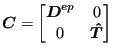

The tangent derived here only applies to the normal directions. It has to be

complemented by a shear part ![]() in the form [20]:

in the form [20]:

|

(452) |

where

|

(453) |

Finally, the tangent matrix

![]() has to be transformed back into

the global system yielding

has to be transformed back into

the global system yielding

![]() :

:

| (454) |

where

![]() is the transformation matrix in equation (A5) in

[20]. Notice that equation (A6) in [20] is wrong and

has to be replaced by the equation above. Similarly the stress is to be

transformed into the global system by:

is the transformation matrix in equation (A5) in

[20]. Notice that equation (A6) in [20] is wrong and

has to be replaced by the equation above. Similarly the stress is to be

transformed into the global system by:

| (455) |