下一个: 热传递 上一级: Types of analysis 上一页: 稳态动力学 目录

In a direct integration dynamic analysis, activated by the

*DYNAMIC keyword, the equation of motion is integrated in

time using the ![]() -method developed by Hilber, Hughes and Taylor

[65] (unless the massless contact method is selected; this method is treated

at the end of this section). The method is implemented exactly as described in

[24]. The parameter

-method developed by Hilber, Hughes and Taylor

[65] (unless the massless contact method is selected; this method is treated

at the end of this section). The method is implemented exactly as described in

[24]. The parameter ![]() lies in the interval [-1/3,0] and

controls the high frequency dissipation:

lies in the interval [-1/3,0] and

controls the high frequency dissipation: ![]() =0 corresponds to the

classical Newmark method inducing no dissipation at all, while

=0 corresponds to the

classical Newmark method inducing no dissipation at all, while ![]() =-1/3

corresponds to maximum dissipation (default is

=-1/3

corresponds to maximum dissipation (default is ![]() =-0.05). The user can choose between an implicit and explicit version of the algorithm. The implicit version (default) is unconditionally stable.

=-0.05). The user can choose between an implicit and explicit version of the algorithm. The implicit version (default) is unconditionally stable.

In the explicit version, triggered by the parameter EXPLICIT on the *DYNAMIC

keyword card, the mass matrix is lumped, and a forward integration scheme is

used so that the solution can be calculated without solving a system of

equations. This corresponds to section 2.11.5 in [24]. The mass

matrix only has to be set up once at the start of each step and no stiffness

matrix is needed. Indeed, the terms in equation (2.475) in

[24] in which the ![]() matrix is used correspond to the internal

forces. They can be calculated directly from the stresses without need to set

up the stiffness matrix. Therefore, each increment is much faster than with the implicit

scheme. Furthermore, in the explicit method no 迭代 are

performed, so each increment consists of exactly one iteration. However, the

explicit scheme is only conditionally stable: in the

matrix is used correspond to the internal

forces. They can be calculated directly from the stresses without need to set

up the stiffness matrix. Therefore, each increment is much faster than with the implicit

scheme. Furthermore, in the explicit method no 迭代 are

performed, so each increment consists of exactly one iteration. However, the

explicit scheme is only conditionally stable: in the ![]() -method, which in

CalculiX is also used for explicit calculations (unless the massless contact

method is selected), the maximum

time step

-method, which in

CalculiX is also used for explicit calculations (unless the massless contact

method is selected), the maximum

time step

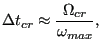

![]() is dictated by:

is dictated by:

|

(516) |

where

![]() is given by Equation (2.477) in [24] and

is given by Equation (2.477) in [24] and

![]() , which is the highest natural frequency of an element,

satisfies for volumetric elements:

, which is the highest natural frequency of an element,

satisfies for volumetric elements:

| (517) |

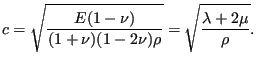

where ![]() is the velocity of sound for the material at stake and

is the velocity of sound for the material at stake and ![]() is the minimum height of the

element. For an isotropic material

is the minimum height of the

element. For an isotropic material ![]() satisfies [68]:

satisfies [68]:

|

(518) |

It corresponds to the wave speed of longitudinal waves, which are faster than

transversal waves, for which the speed amounts to

![]() . For the special case of single crystal materials, which are anistropic

materials characterized by three independent elastic contants, the derivation

is more intricate [68]. Here, the derivation will be given for

general anisotropic materials.

. For the special case of single crystal materials, which are anistropic

materials characterized by three independent elastic contants, the derivation

is more intricate [68]. Here, the derivation will be given for

general anisotropic materials.

First, the difference between the phase velocity and group velocity of a wave is explained. A one-dimensional wave is described by

| (519) |

in which ![]() is the wave number and

is the wave number and ![]() the angular frequency. For

constant values of

the angular frequency. For

constant values of ![]() and

and ![]() the wave has a constant amplitude for

the wave has a constant amplitude for

![]() constant or a wave speed satisfying:

constant or a wave speed satisfying:

|

(520) |

Now, adding to this wave a wave with slightly different wave number and angular frequency one obtains:

where

| (522) |

and

| (523) |

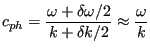

The result in the last line of Equation (521) is the original wave

(

![]() ) with the so-called phase velocity

) with the so-called phase velocity

|

(524) |

modulated by a wave whose velocity amounts to the so-called group velocity:

|

(525) |

The function ![]() versus

versus ![]() is called the dispersion relationship. If

this relationship is linear the phase and group velocity coincide. If not,

they differ.

is called the dispersion relationship. If

this relationship is linear the phase and group velocity coincide. If not,

they differ.

To obtain the phase velocity in three dimensions for an arbitrary material the expression for a three-dimensional planar wave:

| (526) |

where

![]() is the displacement vector, A is the amplitude,

is the displacement vector, A is the amplitude,

![]() is the polarization vector and

is the polarization vector and

![]() is the wave

number vector, is substituted in the general homogeneous equation of motion:

is the wave

number vector, is substituted in the general homogeneous equation of motion:

| (527) |

where

![]() is the stress tensor, a comma denotes

differentiation w.r.t. space and a dot denotes differentiation

w.r.t. time. Indeed, using the elastic relationship

is the stress tensor, a comma denotes

differentiation w.r.t. space and a dot denotes differentiation

w.r.t. time. Indeed, using the elastic relationship

| (528) |

the definition of linear strain

| (529) |

and the symmetry properties of the elasticity tensor

| (530) |

one obtains the following form for the equation of motion:

| (531) |

Sustitution of the wave equation now yields:

| (532) |

Setting

![]() and

and

![]() one obtains the eigenvalue problem

one obtains the eigenvalue problem

where

![]() is the phase velocity we are looking for. Since (denoting

the matrix on the left hand side by

is the phase velocity we are looking for. Since (denoting

the matrix on the left hand side by ![]() ):

):

| (534) |

the left hand matrix is symmetric. Furthermore, for an arbitrary vector

![]() one obtains:

one obtains:

| (535) |

since

![]() (linear elastic energy) and

(linear elastic energy) and ![]() can be considered as the

components of a fictitious strain tensor

can be considered as the

components of a fictitious strain tensor

![]() . This now means that

. This now means that ![]() is positive definite. Therefore, the

特征值 are real and positive.

is positive definite. Therefore, the

特征值 are real and positive.

For an isotropic linear elastic material the elasticity tensor satisfies ([24]):

and component ![]() of the matrix

of the matrix ![]() amounts to:

amounts to:

| (537) |

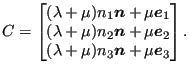

Therefore, ![]() can be thought of consisting of the following row vectors (or

column vectors, since it is a symmetric matrix):

can be thought of consisting of the following row vectors (or

column vectors, since it is a symmetric matrix):

|

(538) |

Setting the determinant of the eigenvalue matrix to zero amounts to:

| (539) |

Multiplying out the different terms leads to:

| (540) |

Using identities such as

![]() finally leads to:

finally leads to:

| (541) |

which leads to a double root ![]() and a single root

and a single root

![]() . Since

. Since

![]() the corresponding phase velocities are

the corresponding phase velocities are

![]() and

and

![]() . The polarization

vectors are the 特征向量 of the system and are obtained by substituting

the 特征值 in the eigenvalue system

. The polarization

vectors are the 特征向量 of the system and are obtained by substituting

the 特征值 in the eigenvalue system ![]() . This leads to the

polarization vectors

. This leads to the

polarization vectors

![]() and

and

![]() for the double root and

for the double root and

![]() for the single root. The former 特征向量 are orthogonal to

the propagation direction of the wave

for the single root. The former 特征向量 are orthogonal to

the propagation direction of the wave

![]() and therefore these are

transversal waves, whereas the latter eigenvector is parallel to the wave

vector and corresponds to a longitudinal wave.

and therefore these are

transversal waves, whereas the latter eigenvector is parallel to the wave

vector and corresponds to a longitudinal wave.

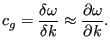

In order to obtain an expression for the group velocity of the wave the

derivative of the angular frequency ![]() w.r.t. the wave number vector

w.r.t. the wave number vector

![]() is needed. Multiplying the eigenvalue Equation [533] with the normalized polarization vector

is needed. Multiplying the eigenvalue Equation [533] with the normalized polarization vector ![]() yields:

yields:

| (542) |

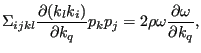

Taking the derivative w.r.t. ![]() leads to:

leads to:

|

(543) |

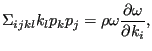

or

![$\displaystyle \Sigma_{ijkl} [k_l \delta_{iq} + \delta_{lq} k_i] p_k p_j = 2 \rho \omega \frac{\partial \omega }{\partial k_q}.$](img1752.png) |

(544) |

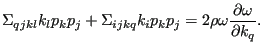

This amounts to:

|

(545) |

Since

![]() the term

the term

![]() equals

equals

![]() , i.e. it is

identical with the first term in the equation. Therefore:

, i.e. it is

identical with the first term in the equation. Therefore:

|

(546) |

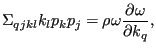

or

|

(547) |

which amounts to:

The latter equation expresses the group velocity as a function of the polarization vector, the wave vector and the phase velocity.

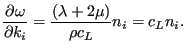

Substituting the isotropic elasticity tensor from Equation [536] leads to:

![$\displaystyle \frac{\partial \omega }{\partial k_i} = \frac{1}{\rho c} [\lambda p_i p_k n_k + \mu p_i p_l n_l + \mu n_i ].$](img1760.png) |

(549) |

For the longitudinal wave, knowing that

![]() ,

,

![]() ,

,

![]() and

and

![]() one gets

one gets

|

(550) |

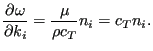

For the transversal waves

![]() and

and

![]() . Therefore:

. Therefore:

|

(551) |

Consequently, for an isotropic elastic material the phase and group velocity coincide. For an anisotropic material, such as a single crystal, this is not necessarily the case.

Now, coming back to the original question of a stable time step in an explicit

dynamic procedure it is clear that the maximal group speed is to be taken. For

an isotropic material this is the longitudinal wave speed. For an anisotropic

material the group speed may depend on the wave vector

![]() . So for a given wave vector Equation

[533] has to be solved to yield the phase velocities

. So for a given wave vector Equation

[533] has to be solved to yield the phase velocities ![]() and the corresponding polarization vectors

and the corresponding polarization vectors

![]() . The latter ones

have to be substituted in Equation [548] to find the group

velocities. Now, the wave vector direction has to be varied so as to find the

maximum group velocity feasible for a material characterized by the specific

elastic tensor

. The latter ones

have to be substituted in Equation [548] to find the group

velocities. Now, the wave vector direction has to be varied so as to find the

maximum group velocity feasible for a material characterized by the specific

elastic tensor

![]() . This velocity is then used to calculate

. This velocity is then used to calculate

![]() and

and

![]() .

.

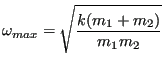

For the contact spring elements, the idealization of a spring with spring

constant ![]() connecting two nodes with nodal masses

connecting two nodes with nodal masses ![]() and

and ![]() is

used. For such a system one obtains:

is

used. For such a system one obtains:

|

(552) |

where ![]() and

and ![]() . For 节点-面罚接触 and

面对面罚接触 the nodal mass on the facial sides can be

obtained by using the shape functions at the spring location.

. For 节点-面罚接触 and

面对面罚接触 the nodal mass on the facial sides can be

obtained by using the shape functions at the spring location.

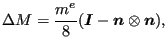

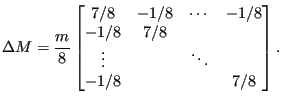

To accelerate explicit dynamic calculations selective mass scaling can be used [73]. It was introduced in CalculiX in the course of a Master Thesis [23]. Applying selective mass scaling the time increment can be increased, which reduces the overall computational time. The selective mass scaling procedure starts from the lumped mass matrix, which for linear elements and one global coordinate direction looks like (examplary for a C3D8-element):

|

(553) |

where ![]() is the total mass of the element. Now, this mass matrix is augmented

by a multiple of itself after removal of the rigid body translational modes:

is the total mass of the element. Now, this mass matrix is augmented

by a multiple of itself after removal of the rigid body translational modes:

|

(554) |

where (writing

![]() as a column vector)

as a column vector)

| (555) |

This leads to:

|

(556) |

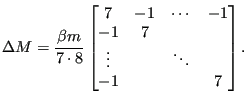

Now, the division by 8 in the denominator of the matrix is approximated by a

division by 7 to yield 1 on the diagonal and a scaling factor ![]() is

introduced:

is

introduced:

|

(557) |

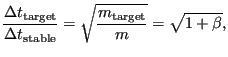

In conclusion, the diagonal elements of matrix ![]() are now modified by a

factor

are now modified by a

factor ![]() . Since the natural frequency

. Since the natural frequency

![]() and

the time increment

and

the time increment

![]() , one can conclude that

, one can conclude that

|

(558) |

from which

![]() . For other element types “7” should be replaced by

. For other element types “7” should be replaced by ![]() and “8” by

and “8” by ![]() ,

where n is the number of nodes in the element. The resulting mass matrix is

now not diagonal any more and a LU-decomposition has to be performed. Since

the mass does not change during the calculation, this decomposition has

to be performed only once at the start of the calculation.

,

where n is the number of nodes in the element. The resulting mass matrix is

now not diagonal any more and a LU-decomposition has to be performed. Since

the mass does not change during the calculation, this decomposition has

to be performed only once at the start of the calculation.

In CalculiX, selective mass scaling is triggered by specifying the minimum time

increment

![]() which the user is willing to tolerate underneath the *DYNAMIC keyword (third

parameter). If for any volumetric element the increment size

which the user is willing to tolerate underneath the *DYNAMIC keyword (third

parameter). If for any volumetric element the increment size

![]() calculated by CalculiX

(based on the wave speed) is less than the

minimum, the mass of this element is automatically selectively scaled. In that

case a message is printed and the

elements for which the mass was redistributed are stored in file

“jobname_WarnElementMassScaled.nam”. This file can be read in any active cgx-session

by typing “read jobname_WarnElementMassScaled.nam inp” and the elements

can be appropriately visualized. If the mass of too many elements is

redistributed, the lowest eigenfrequencies might be affected, leading to wrong

results. Therefore, the maximum allowed time increment should be limited by a

maximum allowed change of the lowest eigenfrequency by, e.g. 1 %. It is the

responsability of the user to check this by performing a

*FREQUENCY calculation in which the desired time step is

provided as the fourth entry underneath the *FREQUENCY card. In addition, the

value of

calculated by CalculiX

(based on the wave speed) is less than the

minimum, the mass of this element is automatically selectively scaled. In that

case a message is printed and the

elements for which the mass was redistributed are stored in file

“jobname_WarnElementMassScaled.nam”. This file can be read in any active cgx-session

by typing “read jobname_WarnElementMassScaled.nam inp” and the elements

can be appropriately visualized. If the mass of too many elements is

redistributed, the lowest eigenfrequencies might be affected, leading to wrong

results. Therefore, the maximum allowed time increment should be limited by a

maximum allowed change of the lowest eigenfrequency by, e.g. 1 %. It is the

responsability of the user to check this by performing a

*FREQUENCY calculation in which the desired time step is

provided as the fourth entry underneath the *FREQUENCY card. In addition, the

value of ![]() can also be specified.

can also be specified.

For spring elements the mimimum time increment specified by the user is obtained by reducing the spring stiffness. CalculiX stores the maximum spring stiffness reduction to standard output.

Without a minimum time increment no selective mass scaling nor spring stiffness reduction is applied.

The following damping options are available:

For explicit dynamic calculations an additional hard contact formulation has been coded within a procedure characterized by:

From now on the method will be called the massless explicit dynamics method. Its implementation closely follows the frictional flow diagram in [69]. From this publication it is clear that the contactless stiffness matrix is needed. The submatrix related to the contact degrees of freedom (master and slave) is used to set up and solve an inclusion problem in an implicit way. The other submatrices are used to calculate the right hand side of the dynamic equations. The left hand side of these equations is made up of a combination of the mass and damping matrix. It is assumed that these latter matrices do not change during the step, therefore, they can be factorized once at the beginning of the step.

If the NLGEOM parameter is not used on the *STEP card and if all materials are linear the stiffness matrix is calculated only once at the beginning of the step, else it is calculated in each increment which substantially increases the computational time.

Limitations right now include:

The method is triggered by the option TYPE=MASSLESS on all *CONTACT PAIR cards in a *DYNAMIC, EXPLICIT procedure only. In a *STATIC or *DYNAMIC implicit step the contact definition is replaced by TYPE=NODE TO SURFACE. Note that within one 输入卡 only one type of *CONTACT PAIR is allowed. Since the contact is hard, the only parameter is the friction coefficient.

In the massless explicit dynamics method selective mass scaling is also

used. It is triggered in exactly the same way as for the ![]() -method,

i.e. by specifying a minimum time increment exceeding the stable time

increment. In contrast to the

-method,

i.e. by specifying a minimum time increment exceeding the stable time

increment. In contrast to the ![]() -method the change of mass matrix is

added to the unlumped mass. Selective mass scaling is particularly

advantageous in the presence of few very small elements which lead to an

extremely small stable time increment.

-method the change of mass matrix is

added to the unlumped mass. Selective mass scaling is particularly

advantageous in the presence of few very small elements which lead to an

extremely small stable time increment.

For all dynamic calculations (隐式动力学, explicit dynamics with 罚接触 or explicit dynamics with massless contact) a energy balance can be requested. For 隐式动力学 this is done by default, for explicit dynamics the balance is calculated if the user has requested the output variable ENER underneath a *EL PRINT, *EL FILE or *ELEMENT OUTPUT keyword. This increases the computational time.